THJ80 – SAFE OPERATION VIA REMOTE CONTROL NO PERSONNEL AT RISK – MOBILE, EFFICIENT, AND INNOVATIVE!

Our THJ80 system expands our product portfolio with a groundbreaking product, the smaller sibling of the Turbo Hydro Jet Box. This innovative module provides cutting-edge solutions for fire protection and disaster response.

It is fully customizable and supports fire departments, authorities, and disaster relief organizations worldwide in safely addressing their daily challenges from a distance.

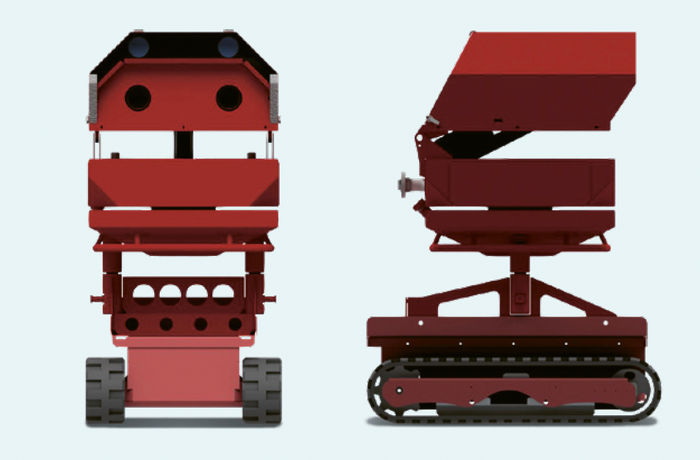

The module can be easily mounted on existing fire vehicles, aerial ladders, or remote-controlled tracked chassis and put into operation immediately.

THJ80 demonstration in the forest

The Key Features

due to a large throwing range (up to 60m) and wireless remote control (up to 100m).

utilizing tiny water droplets with high cooling capacity and extensive coverage.

through integration into roll-off containers, fire vehicles, or trailers, as well as standalone operation.

through a single operator, effective water consumption, and reduced wastewater.

for high user-friendliness and versatility.

Fields of Application:

with or without foam

allowing targeted cooling of objects to prevent overheating, minimize re-ignition, and ensure the overall protection of buildings and facilities.

between burning and endangered objects to contain fires and minimize damage.

for diluting and washing out hazardous gases, particles, and dangerous chemicals to reduce environmental hazards.

for large buildings, warehouses, parking structures, and tunnels to remove smoke and ensure safety during emergency situations.

Technical data & performance data of THJ80

- THJ80 L/W/H = approx. 1.150 × 740 × 1.500 mm

- Jet engines modified jet engines

- Weight approx. 100 kg (plus diesel 60 l)

- Pivoting range canopy horizontal 270°, vertical –10° to +45°

- Electrical system onboard, independent

- Fuel supply onboard, independent

- Operating fluids onboard fuel, oil

- Operating fluids external water/foam (1 × C-Storz hose)

- Driving power approx. 2 × 50 hp (2 × kW 37)

- Air flow approx. 2 × 1 m³/s

- Spraying width approx. 60 m

- Spraying height approx. 30 m

- Spraying surface 180° approx. 40 m²

- Precipitation rate approx. 2 – 4 l/(m² × min)

- Foam concentration approx. foam 0 – 9 %